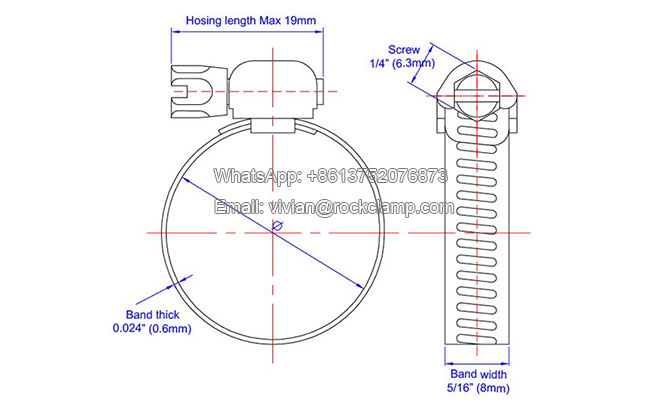

Band width: 5/16” (8mm)

Band thick: 0.024” (0.6mm)

Screw size: 1/4” (6.3mm)

Material: W2

Free running torque: 6 in-lbs (0.7 Nm)

Suggested installation torque: 18.5 in-lbs (2.1 Nm)

Description:

The W2 tiny hose clamps (worm drive hose clip) is normally called micro hose clamps, the tiny hose clamps are manufactured through precision stamping technology, featuring an ultra-thin and lightweight structural design. Those micro hose clamps compact construction provides optimal compatibility with small-diameter hoses (Φ6-25mm), while demonstrating exceptional sealing performance under low-pressure conditions. With its space-saving profile, this tiny hose clamps are particularly suited for demanding applications in precision instruments, laboratory analytical equipment, and medical devices where strict spatial constraints exist. It represents an ideal sealing solution for confined spaces, combining reliable performance with minimal footprint.

Material:

W2 - Hosing and band stainless steel 201 or 301, Screw carbon steel with zinc/nickel plated

This worm drive hose clip utilizes highly corrosion-resistant stainless steel band, offering superior rust protection. Compared to galvanized band hose clamp, this W2 worm drive hose clip is particularly suitable for humid or corrosive environments. The screw material zinc-plated iron maintains fundamental anti-corrosion properties while significantly reducing costs versus all parts stainless steel hose clamp.

Feature:

• Precision-stamped construction

• Low-profile, lightweight design

• 6-25mm diameter range compatibility

• ≤0.5MPa pressure rating

• Space-optimized for compact installations

Drawing:

Dimension chart:

| 5/16"(8mm) band width Material: W2 201/304 |

|||||

| Part No | SAE Size | Dimension | Qty/Ctn | Meast in cm | |

| mm | in inch | ||||

| AM8W216 | 4 | 6-16 | 0.25"-0.62" | 2000 | 38×27×14 |

| AM8W220 | 6 | 11-20 | 0.44"- 0.78" | 2000 | 38×27×19 |

| AM8W223 | 8 | 13-23 | 0.5"- 0.91" | 2000 | 38×27×17 |

| AM8W227 | 10 | 14-27 | 0.56"- 1.06" | 2000 | 38×27×29 |

| AM8W232 | 12 | 18-32 | 0.69"- 1.25" | 2000 | 38×27×34 |

Micro hose clamps Application:

The material W2 delivers exceptional cost-performance, offering significantly better corrosion resistance than galvanized steel products(W1) while achieving 25-35% cost reduction compared to all stainless steel hose clamp (W4) alternatives - striking an optimal balance between performance and affordability.

Specifically designed for low-pressure piping connections, its typical applications include:

• Industrial fluid systems

• Automotive peripheral line repairs

• HVAC ductwork support

• Agricultural irrigation systems

Package:small bag/box + outer carton + pallet