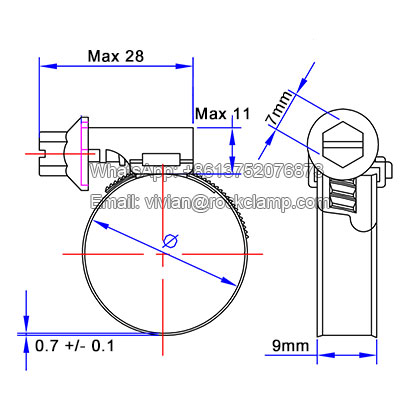

Band width: 9mm

Band thick: 0.65mm

Screw size: 7mm

Material: W2, W4

Free running torque: 6 in-lbs (0.7 Nm)

Suggested installation torque: 38 in-lbs (4.5 Nm)

Description:

The Germany type solid hosing hose clamp is also know as european style hose clamps. They are made of high-quality stainless steel bands and features a worm gear mechanism for precise size adjustment. Its unique non-ventilated design, combined with a reinforced buckle cover structure, ensures outstanding sealing performance while significantly enhancing the clamp's overall strength and durability. This reinforced design is particularly suitable for demanding applications such as high-pressure and high-vibration pipeline connections.

Material:

W2 - Hosing and band stainless steel 201/301/304, screw carbon steel with zinc/nickel plated

W4 - All parts stainless steel 201/301/304. (screw, hosing and band)

Features:

The european style hose clamps features the non-perforated band and solid hosing design, which effectively shields the steel band from corrosive agents, preventing damage caused by liquid penetration or contaminant ingress, thereby enhancing long-term durability.

- Compliant with DIN 3017 standard, ensuring international quality compliance.

- Unique offset non-welded housing design prevents hose damage from over-tightening, enhancing durability.

- Short housing saddle design provides a smooth base for efficient sealing and leak prevention.

- Offset housing head design improves torque transmission for easier installation and secure fastening.

Drawing:

Dimension chart:

| 9mm european style hose clamps | ||||

| Part No | Dimension range |

Part No | Dimension range |

|

| SHGM9W12 | 8-12 | SHGM9W45 | 30-45 | |

| SHGM9W16 | 10-16 | SHGM9W50 | 32-50 | |

| SHGM9W20 | 12-20 | SHGM9W60 | 40-60 | |

| SHGM9W22 | 12-22 | SHGM9W70 | 50-70 | |

| SHGM9W25 | 16-25 | SHGM9W80 | 60-80 | |

| SHGM9W27 | 16-27 | SHGM9W90 | 70-90 | |

| SHGM9W32 | 20-32 | SHGM9W100 | 80-100 | |

| SHGM9W35 | 23-35 | ... | ... | |

| SHGM9W40 | 25-40 | SHGM9W200 | 180-200 | |

Application:

With its fully enclosed steel band design, corrosion-resistant construction, and enhanced torque performance, this clamp is specifically designed for demanding operating conditions, including:

- Hydraulic lines, fuel systems, coolant pipelines, and other connections requiring high sealing integrity.

- Ideal for pressure-resistant pipe fittings in construction machinery, marine, and automotive industries.

- The non-welded housing design avoids fracture risks caused by stress concentration.

- Chemical, petroleum, and offshore engineering applications exposed to acid/alkali/salt spray conditions, where stainless steel material and non-vented structure provide combined corrosion resistance.

Package:

Small bag/box + outer carton + pallet