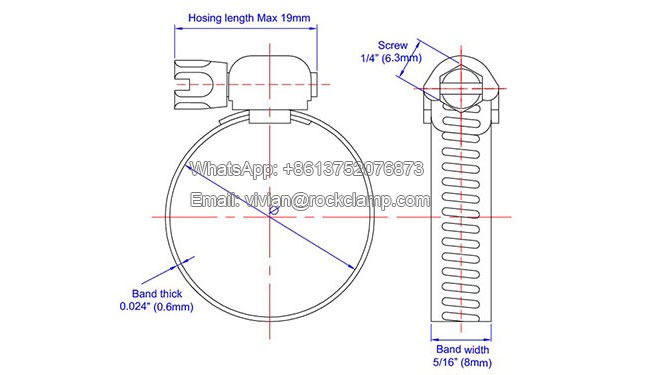

Band width: 5/16” (8mm)

Band thick: 0.024” (0.6mm)

Screw size: 1/4” (6.3mm)

Material: W1- Screw, hosing and band carton steel with zinc plated

Free running torque: 6 in-lbs (0.7 Nm)

Suggested installation torque: 18.5 in-lbs (2.1 Nm)

Description:

The small hose clamps, or thin hose clamps are made of material galvanized steel, they are specifically designed for small-diameter hoses, suitable for low-pressure applications, with a compact structure that meets installation requirements in tight spaces.

The thin hose clamps utilize a captive worm gear screw fixed to the steel band. The band features perforations running along its entire length. The threads of the worm screw engage with these perforations, causing the hose clamp diameter to expand or contract as the screw is tightened or loosened.

Material:

W1 - All parts carbon steel with zinc plated. (screw, hosing and band)

Feature:

Compared to stainless steel clamps, the thin hose clamps are more affordable, making them suitable for cost-sensitive projects or bulk purchases. They feature lighter weight, ideal for weight-critical applications in compact equipment or portable devices.

These small hose clamps offer:

• Optimized band hardness - Resists deformation during installation while allowing hand-tool tightening

• Zinc-plated protection - Provides superior rust resistance compared to plain iron, performing well in dry or mildly corrosive environments

Drawing:

Dimension chart:

| 5/16"(8mm) band width Material: W1 - all parts carbon steel with zinc plated |

|||||

| Part No | SAE Size | Dimension | Qty/Ctn | Meast in cm | |

| mm | in inch | ||||

| AM8W116 | 4 | 6-16 | 0.25"-0.62" | 2000 | 38×27×14 |

| AM8W120 | 6 | 11-20 | 0.44"- 0.78" | 2000 | 38×27×19 |

| AM8W123 | 8 | 13-23 | 0.5"- 0.91" | 2000 | 38×27×17 |

| AM8W127 | 10 | 14-27 | 0.56"- 1.06" | 2000 | 38×27×29 |

| AM8W132 | 12 | 18-32 | 0.69"- 1.25" | 2000 | 38×27×34 |

Application:

Those small hose clamps provide reliable sealing for non-corrosive media including water, air, and lubricating oil in low-pressure pipeline systems (operating pressure ≤0.6MPa). Its superior compatibility accommodates various hose materials such as natural rubber, synthetic rubber, and PVC polymer hoses. The innovative structural design ensures optimal clamping force while minimizing mechanical damage to hose walls, effectively extending service life of connected hoses.

Package:small bag/box + outer carton + pallet