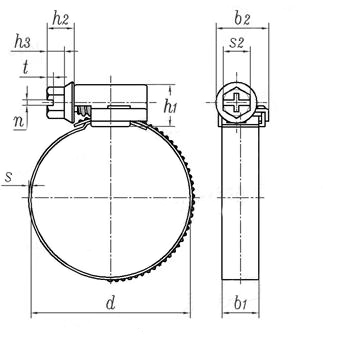

Band width: 9mm/12mm

Band thick: 0.6mm

Screw size: 7mm

Material: W2 201/301/304

Free running torque: 6 in-lbs (0.7 Nm)

Suggested installation torque: 30 in-lbs (3.5 Nm)

DIN 3017 is a German Industrial Standard that specifies the requirements for high-quality worm drive hose clamps. It is one of the most recognized and respected standards for hose clamps globally, particularly in engineering and industries where reliability is critical. W2 stainless steel Germany type worm drive hose clamp is one type of din 3017 hose clamps.

Key Features of DIN 3017 Clamps

Materials:

Band: Must be made from stainless steel. The most common grades are:

A2 (304 stainless steel): For general corrosion resistance (e.g., automotive, industrial).

A4 (316 stainless steel): For enhanced corrosion resistance, especially in marine and chemical environments (resistant to saltwater and acids).

Screw and Housing: Also typically manufactured from stainless steel (A2 or A4) to ensure overall corrosion resistance and prevent galvanic corrosion between different metals.

Performance and Testing:

The standard sets rigorous benchmarks that clamps must meet:

Tensile Strength: The clamp must withstand a specified minimum pulling force without the band breaking or pulling out of the housing.

Pressure Resistance: It must seal a connection without leakage or failure at a defined proof pressure.

Vibration Resistance: The positive-lock mechanism is inherently designed to resist loosening under severe vibration.

Torque Strength: The screw must withstand a minimum torque without stripping.

Common Applications

DIN 3017 clamps are the preferred choice in applications where failure is not an option:

Automotive: Turbocharger and supercharger intercooler pipes, charge air systems, high-performance coolant and oil lines.

Marine: Engine room plumbing, fuel lines, cooling systems exposed to saltwater.

Aerospace: Ground support equipment and non-critical aircraft systems.

Industrial Machinery: Hydraulic systems, compressed air lines, chemical processing equipment.

Food and Beverage: When made from A4 (316) stainless steel, they are suitable for sanitary and wash-down environments.

DIN 3017 P-Clamps: Your Guide to High-Pressure & Heavy-Duty Securing

DIN 3017 clamps are engineered for high-pressure and high-vibration environments where standard clamps fail. Their defining feature is the continuous, fully enclosed metal band with a robust rubber liner, creating a superior 360° seal and grip. This makes them the definitive choice for containing high-pressure hoses and pipes in demanding applications.

Specifically, they are indispensable in commercial vehicle and heavy-duty machinery systems. Install them to securely route and protect critical cooling system hoses, hydraulic lines, and fuel lines that experience extreme pulsation and thermal cycling. In industrial settings, use DIN 3017 clamps to secure pipe joints and conduits in plant machinery, ensuring leak-proof performance and exceptional vibration damping.

To install, select a clamp with an inner diameter matching your hose/pipe OD. Drill mounting holes through the integrated lugs, insert the assembly, and fasten with the specified bolt. Torque evenly to compress the liner without over-tightening. This guarantees a secure, long-lasting hold that protects against abrasion, fluid leaks, and system failure in the most challenging high-stress environments.