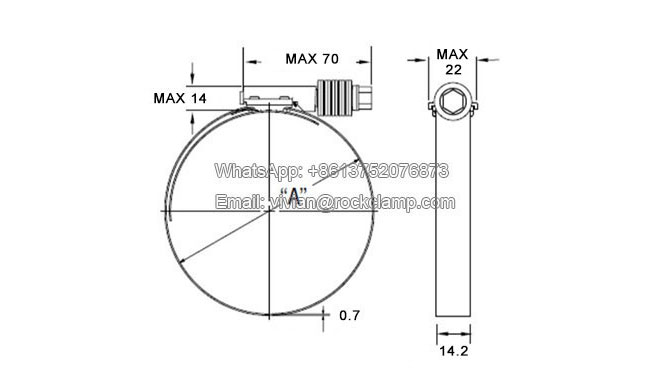

Band width: 14.2mm

Material: W2/W4

Free running torque: 6 in-lbs (0.7 Nm)

Suggested installation torque: 64 in-lbs (7.5 Nm)

Description:

The 14.2mm band width constant tension clamp is a robust high-strength pipe fastening system specifically engineered for demanding industrial applications. Utilizing a heavy-duty worm gear mechanism, it delivers optimal performance for critical pipeline connections across petrochemical, heavy machinery, and marine engineering sectors.

Constant tension hose clamps Component:

Band, hosing, screw, washers

Constant tension hose clamps Material:

W2 - Band and hosing SS301/304, screw galvanized steel, washer SS410.

W4 - Band, hosing and screw SS301/304, washer SS410.

Features:

Constant tension clamp maintains predetermined tension force regardless of thermal cycling or vibration, and compensates automatically for pipe expansion/contraction.

- The stainless steel material is corrosion-resistant suitable for offshore/marine applications.

- Worm gear design with anti-reverse technology is vibration-resistant even in high-frequency environments and prevents spontaneous loosening.

- It has adjustable diameter range typically from 1/2" to 24", which are compatible with multiple pipe materials (carbon steel, stainless, HDPE, etc.)

Drawing:

Dimension chart:

| Constant tension clamp | |||

| Part No | Band Width | Dimension Range | |

| in mm | in inch | ||

| CT14W32 | 14.2 *0.7 | 17-32 | 11/16"-1 1/4" |

| CT14W38 | 14.2 *0.7 | 21-38 | 13/16"- 1 1/2" |

| CT14W44 | 14.2 *0.7 | 21-44 | 13/16"- 1 3/4" |

| CT14W51 | 14.2 *0.7 | 27-51 | 1 1/16"- 2" |

| CT14W57 | 14.2 *0.7 | 33-57 | 1 5/16"- 2 1/4" |

| CT14W64 | 14.2 *0.7 | 40-64 | 1 9/16"- 2 1/2" |

| CT14W70 | 14.2 *0.7 | 46-70 | 1 13/16"- 2 3/4" |

| CT14W76 | 14.2 *0.7 | 52-76 | 2 1/16"- 3" |

| CT14W83 | 14.2 *0.7 | 59-83 | 2 5/16"- 3 1/4" |

| CT14W89 | 14.2 *0.7 | 65-89 | 2 9/16"- 3 1/2" |

Workshop:

Application:

The constant tension hose clamps are precision-engineered fasteners designed to maintain a fixed clamping force even under vibration, thermal cycling, or dynamic loads. They are widely used in industries where bolt loosening or gasket failure can lead to leaks, safety hazards, or equipment damage.

- Flange Bolt Securing: Prevents loosening in high-pressure pipe flanges

- Wellhead Equipment: Maintains seal integrity on Christmas trees and manifolds

- Subsea Connections: Corrosion-resistant designs for underwater pipelines

- Turbine Casing Bolts: Ensures uniform gasket compression in steam turbines

- Heat Exchangers: Resists thermal cycling in condenser and boiler systems

- Reactor Vessel Clamping: Keeps consistent load on high-pressure reactors

- Pump/Valve Connections: Prevents flange leaks in aggressive chemical service

- High-Temperature Lines: Handles expansion in furnace and reformer piping

Package: small bag/box + outer carton + pallet