Band width: 19mm (0.75”)

Material: W4

Free running torque: 6 in-lbs (0.7 Nm)

Suggested installation torque: 77 in-lbs (9 Nm)

Description:

Stainless steel t bolt clamps provide superior sealing performance for high-pressure applications, featuring a heavy-duty stainless steel band 301/304 with a distinctive T-shaped bolt mechanism that delivers 50% higher clamping force than standard worm-drive clamps. Their reinforced construction withstands extreme pressures and temperatures, while the smooth inner surface prevents hose damage, making them ideal for demanding automotive, industrial, and marine applications requiring vibration resistance and leak-proof reliability.

Material:

W4 - All parts stainless steel 301/304

The stainless steel t bolt clamps delivers superior corrosion resistance and long-term reliability in harsh environments. This monolithic material design eliminates galvanic corrosion risks between components while maintaining high tensile strength, making it ideal for critical applications in marine, chemical processing, and food industries where hygiene and durability are paramount. The uniform thermal expansion characteristics ensure stable sealing pressure under temperature fluctuation.

Features:

- 19mm widened band design increases load-bearing capacity by 40%.

- Stainless steel band 0.6mm thickness specially hardened for tensile strength.

- M6 fine-thread adjustment bolt enables ±0.5mm-level precise diameter control.

- Self-locking nut with integrated nylon retaining ring.

- Anti-slip knurling on bolt head enhances wrench grip

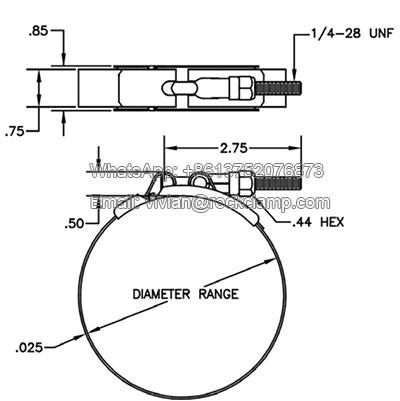

Drawing:

Dimension chart:

| Stainless steel t bolt clamps | ||||||

| Part No | Clamping Range / Dimension | Part No | Clamping Range / Dimension | |||

| in mm | in inch | in mm | in inch | |||

| TBW440 | 37-40 | 1.44"-1.56" | TBW4116 | 108-116 | 4.31" - 4.62" | |

| TBW449 | 43-49 | 1.69"- 1.94" | TBW4122 | 114-122 | 4.56" - 4.87" | |

| TBW452 | 46-52 | 1.18"- 2.06" | TBW4129 | 121-129 | 4.81" - 5.12" | |

| TBW457 | 51-57 | 2.06"- 2.31" | TBW4135 | 127-135 | 5.06" - 5.37" | |

| TBW465 | 58-65 | 2.31"- 2.62" | TBW4141 | 133-141 | 5.31" - 5.62" | |

| TBW472 | 64-72 | 2.56"- 2.87" | TBW4148 | 140-148 | 5.56" - 5.87" | |

| TBW478 | 70-78 | 2.81" - 3.12" | TBW4154 | 146-154 | 5.81" - 6.52" | |

| TBW484 | 76-84 | 2.94" - 3.25" | TBW4160 | 152-160 | 6.06" - 6.37" | |

| TBW491 | 83-91 | 3.31" - 3.62" | TBW4173 | 165-173 | 6.56" - 6.87" | |

| TBW497 | 89-97 | 3.56" - 3.87" | TBW4186 | 178-186 | 7.06" - 7.37" | |

| TBW4103 | 95-103 | 3.81" - 4.12" | TBW4192 | 184-192 | 7.31" - 7.62" | |

| TBW4110 | 102-110 | 4.06" - 4.37" | TBW4200 | 192-200 | 7.56" - 7.87" | |

Application:

It is engineered for extreme environments where maximum corrosion resistance is critical, including marine applications (ship piping/offshore platforms), chemical processing plants, pharmaceutical sterile systems, and coastal infrastructure. Its stainless steel construction withstands prolonged saltwater exposure and high-pressure steam cleaning. The uniform material composition eliminates galvanic corrosion risks, making it essential for permanent installations such as desalination plant pipe connections and nuclear facility coolant systems etc.

Package: small bag/box + outer carton + pallet