Band width: 19mm (0.75”)

Material: W2 301/W2 304

Free running torque: 6 in-lbs (0.7 Nm)

Suggested installation torque: 77 in-lbs (9 Nm)

Description:

Spring loaded pipe clamps (Spring loaded clamps) combine the robust sealing of traditional T-bolt designs with an integrated conical spring that automatically maintains optimal clamping force, compensating for thermal expansion, vibration, and hose material relaxation. These heavy-duty clamps feature precision-engineered springs positioned under the bolt head to provide constant pressure even during temperature fluctuations from -50°C to 700°C, eliminating the need for retightening in dynamic applications like turbocharger systems, aerospace hydraulics, and high-vibration industrial machinery where standard clamps would loosen over time.

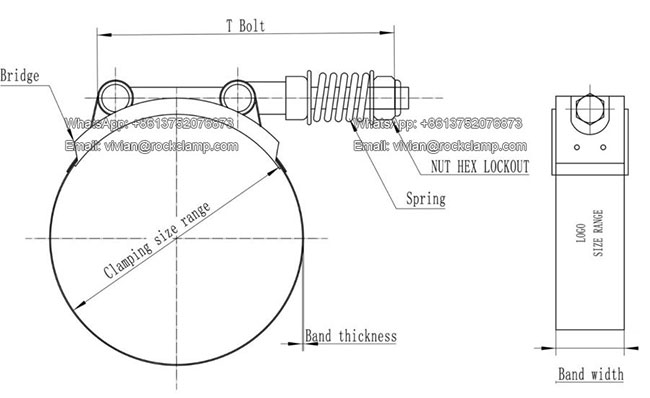

Spring loaded clamps Component:

Band, bridge, trunnion, cap, spring, bolt, nut.

Material:

W2 - Band, Bridge,Trunnion, Cap AISI 300 stainless steel; Bolt, Nut, Spirng carbon steel with zinc plated

Spring loaded clamps Features:

- Integrated zinc-plated spring (±1.2mm travel) automatically compensates for seal loosening caused by thermal expansion or vibration, reducing maintenance tightening needs by 80% compared to standard clamps.

- Zinc-plated (≥8μm) spring/bolt/nut withstands 96-hour salt spray testing, ideal for non-aggressive environments.

- Trapezoidal-thread T-bolt (0.15-0.20 friction coefficient) enables precise torque control (recommended 25-35Nm).

- The bridge’s rolled/flanged edge prevents pipe damage during installation and operation.

- The electric welding of band and bridge ensures a strong, permanent bond between the bridge and band, improving structural integrity.

Drawing:

Dimension chart:

| Spring loaded pipe clamps | ||||||

| Part No | Clamping Range / Dimension | Part No | Clamping Range / Dimension | |||

| in mm | in inch | in mm | in inch | |||

| TBSW270 | 63-70 | 2.48" - 2.76" | TBW2109 | 102-109 | 4.02" - 4.29" | |

| TBSW275 | 67-75 | 2.64" - 2.95" | TBW2110 | 103-110 | 4.06" - 4.33" | |

| TBSW278 | 70-78 | 2.76" - 3.07" | TBW2113 | 105-113 | 4.13" - 4.45" | |

| TBSW280 | 72-80 | 2.83" - 3.15" | TBW2115 | 107-115 | 4.21" - 4.53" | |

| TBSW281 | 73-81 | 2.87" - 3.19" | TBW2116 | 108-116 | 4.25" - 4.57" | |

| TBSW284 | 76-84 | 2.99" - 3.31" | TBW2119 | 111-119 | 4.37" - 4.69" | |

| TBSW285 | 77-85 | 3.03" - 3.35" | TBW2120 | 112-120 | 4.41" - 4.72" | |

| TBSW287 | 79-87 | 3.11" - 3.43" | TBW2122 | 114-122 | 4.49" - 4.8" | |

| TBSW290 | 83-90 | 3.27" - 3.54" | TBW2138 | 130-138 | 5.12" - 5.43" | |

| TBSW294 | 86-94 | 3.39" - 3.7" | TBW2140 | 132-140 | 5.2" - 5.51" | |

| TBSW295 | 87-95 | 3.43" - 3.74" | TBW2146 | 138-146 | 5.43" - 5.75" | |

| TBSW297 | 89-97 | 3.5" - 3.82" | TBW2148 | 140-148 | 5.51" - 5.83" | |

| TBSW2100 | 92-100 | 3.62" - 3.94" | TBW2160 | 152-160 | 5.98" - 6.3" | |

| TBSW2103 | 95-103 | 3.74" - 4.06" | TBW2164 | 155-164 | 6.1" - 6.46" | |

| TBSW2106 | 99-106 | 3.9" - 4.17" | TBW2190 | 182-190 | 7.17" - 7.48" | |

Spring loaded pipe clamps Application:

- Automotive cooling systems

- HVAC ducting

- Low-pressure hydraulic circuits (<10Bar)

- Agricultural machinery fuel lines

Package: small bag/box + outer carton + pallet